Choosing the right hay fork for your Kubota tractor significantly impacts your farming efficiency and sustainability. This guide provides a comprehensive overview, from selecting the ideal fork to troubleshooting common issues, ensuring you maximize your operation's productivity and minimize environmental impact. For added comfort, consider a comfortable seat.

Selecting the Right Hay Fork

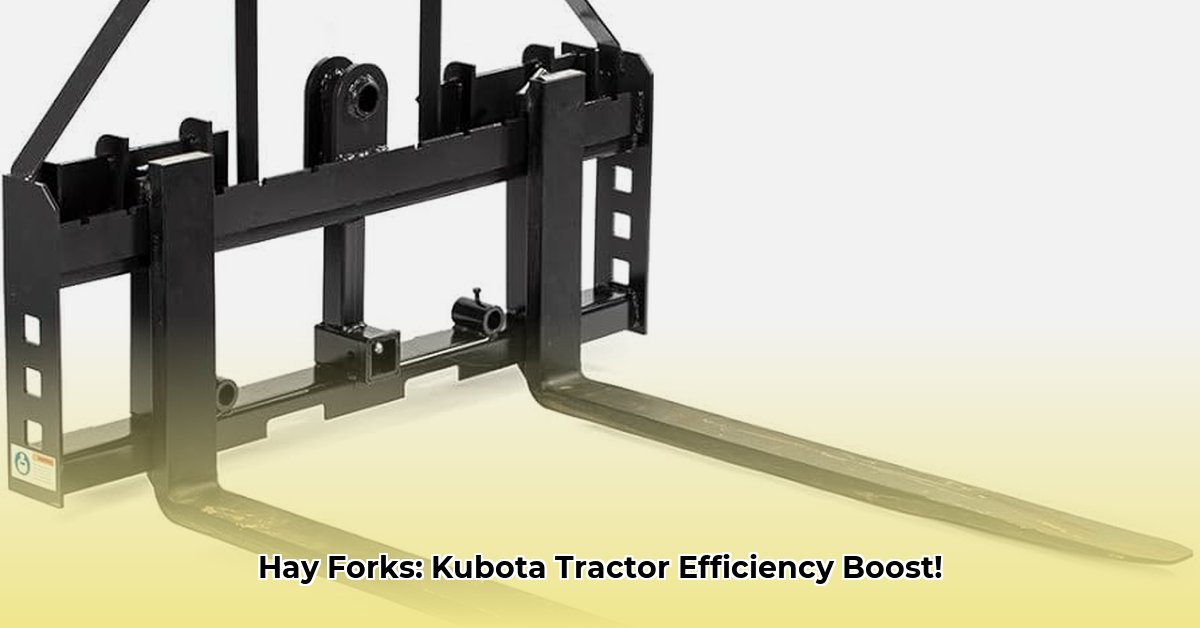

Several factors influence your hay fork choice. The three main types are single-tine, double-tine, and grapple forks. Each offers different capabilities and suits various needs and Kubota models. Which type is best for your operation?

Single-Tine Forks: These are the simplest and most economical option, ideal for smaller bales and lighter-duty work. They're easy to maintain but have a lower lift capacity. Think of them as ideal for smaller Kubota models or limited-scale operations.

Double-Tine Forks: Offering increased stability and higher lift capacity than single-tines, these are a popular choice for medium-sized operations. They strike a balance between capacity and affordability.

Grapple Forks: The most versatile and powerful option, grapple forks are designed for handling large square or round bales efficiently. Their clamping mechanism provides a secure grip, minimizing bale slippage and increasing safety. However, they are the most expensive and require more maintenance.

The following table summarizes key differences:

| Hay Fork Type | Typical Lift Capacity (lbs) | Tine Material | Pros | Cons | Best Suited For Kubota Models |

|---|---|---|---|---|---|

| Single-Tine | 500 - 1500 | Steel, Hardened Steel | Affordable, easy maintenance, suitable for smaller bales | Lower lift capacity, less stable for larger loads | BX, L Series |

| Double-Tine | 1000 - 3000 | Steel, Hardened Steel | Improved stability, higher capacity than single-tine | More expensive than single-tine | B, L, M Series |

| Grapple Fork | 1500 - 4000+ | Steel, Hardened Steel | High capacity, versatile, secure grip | Most expensive, more complex maintenance | M Series, and larger models |

Important Considerations: Always consult your Kubota tractor's owner's manual to determine its maximum lift capacity. Never exceed this limit; it's crucial for safety and prevents equipment damage. The tine material also plays a role; hardened steel offers superior durability and longevity, although it comes at a higher cost.

Installing Your Hay Fork: A Step-by-Step Guide

Correct installation is critical for safe and efficient operation. Always prioritize safety. Before proceeding: engage the parking brake and turn off the tractor engine.

Quick Hitch Attachment (Recommended): If your Kubota has a quick-attach system, aligning the fork is generally straightforward; secure it following the manufacturer's instructions.

Connecting Hydraulic Lines: Carefully connect the hydraulic hoses to the corresponding ports on your tractor. Double-check for secure, leak-free connections. Any leakage should be addressed immediately.

Test Lift: Once connected, slowly raise and lower the fork to confirm smooth operation. Monitor for leaks and ensure proper hydraulic function before operating at full capacity. Don't rush this step; a thorough check saves time and prevents costly repairs later.

Operating and Maintaining Your Hay Fork

Efficient use and regular maintenance prolong your hay fork's lifespan and ensures optimal performance. This contributes to both your productivity and your bottom line.

Efficient Operation:

Loading: Approach the bale slowly and carefully center the tines. Lift smoothly to avoid jarring movements.

Transporting: Maintain a consistent pace, avoiding sudden braking or sharp turns, which can cause bale shifting.

Unloading: Lower the bale gently to prevent damage to the bale, the fork, or your surrounding environment.

Routine Maintenance:

Lubrication: Regularly lubricate moving parts as recommended by the manufacturer. This prevents premature wear and tear.

Inspection: Check for wear and tear, particularly on the tines. Replace damaged components promptly; delaying repairs could result in heavier damage and costly replacements.

Cleaning: Clean the fork after each use to remove mud, debris, and other materials that could accelerate corrosion or cause damage.

Troubleshooting

Here are solutions to common problems:

Fork Not Lifting: Verify hydraulic fluid levels, inspect lines for leaks or blockages, and ensure secure connections.

Uneven Lifting: Ensure the bale is centered on the tines. If the issue persists, a mechanical or hydraulic problem may exist.

Case Study: Farmer Jane's Success

Farmer Jane, using a grapple fork, improved efficiency significantly: “The difference is remarkable. I move more hay in less time, freeing up time for other critical farm tasks. The investment has been more than worthwhile.” This illustrates the productivity increases achievable through selecting appropriate equipment.

Sustainability and Efficiency: The Bigger Picture

Efficient hay handling practices are crucial for sustainable farming. Minimizing fuel consumption and reducing soil compaction positively impact both the environment and your farming costs. By choosing the correct hay fork and adhering to maintenance guidelines, you actively contribute to more environmentally friendly and productive farming operations. This is not just about the bottom line; it's about responsible land stewardship and sustainable agricultural practices.